Anodizing

Quality Aluminum Anodizing for lengths up to 30' 6"

Original specifications for anodizing were all proprietary with each company having its own method. The Aluminum Association unified the main specifications (Publication 45: “Designation system for aluminum finishes”). However, the publication is only a reference on the final mechanical, chemical and coating parameters, and it does not fully provide the picture on how to achieve those designations. In general, the process is described by the following designation:

Original specifications for anodizing were all proprietary with each company having its own method. The Aluminum Association unified the main specifications (Publication 45: “Designation system for aluminum finishes”). However, the publication is only a reference on the final mechanical, chemical and coating parameters, and it does not fully provide the picture on how to achieve those designations. In general, the process is described by the following designation:

AA M33 C22 A44

AA = Aluminum Association

M10 = Unspecified (e.g. M33 Mechanical Finished)

C22 = Medium matte etched (Example: Sodium hydroxide 130 – 150 °F for 5 to 10 minutes)

A44 = Architectural Class I (0.7 mil and greater coating), Deposited Color Coating (Example of Method: 15 % H2SO4 used at 70 ± 2 °F at 12 amp per sq. ft for 60 min, followed by electrolytic deposition of inorganic pigment in the coating)

The AAMA designation translates to CFC’s product codes according to the following table:

|

Available Colors |

Class I Finish |

Other Names |

AAMA Designation for Aluminum Finishes* |

AAMA Specification |

|

Clear |

CFC-215 |

Class I (>0.7mil) |

AA-M10C22A41 |

AAMA 611 |

|

Light Bronze |

CFC-442 |

2-Step Champagne |

AA-M10C22A44 |

AAMA 611 |

|

Medium Bronze |

CFC-443 |

2-Step Medium Bronze |

AA-M10C22A44 |

AAMA 611 |

|

Dark Bronze |

CFC-444 |

2-Step Dark Bronze |

AA-M10C22A44 |

AAMA 611 |

|

Black |

CFC-446 |

2-Step Black |

AA-M10C22A44 |

AAMA 611 |

|

Available Colors |

Class II Finish |

Other Names |

AAMA Designation for Aluminum Finishes* |

AAMA Specification |

|

Clear |

CFC-204 |

Class II(0.4-0.7mil) |

AA-M10C22A31 |

AAMA 611 |

|

Light Bronze |

CFC-342 |

2-Step Champagne |

AA-M10C22A34 |

AAMA 611 |

|

Medium Bronze |

CFC-343 |

2-Step Medium Bronze |

AA-M10C22A34 |

AAMA 611 |

|

Dark Bronze |

CFC-344 |

2-Step Dark Bronze |

AA-M10C22A34 |

AAMA 611 |

|

Black |

CFC-346 |

2-Step Black |

AA-M10C22A34 |

AAMA 611 |

|

Available Colors |

Type III Finish |

Other Names |

MIL Designation for Aluminum Finishes* |

|

Natural Clear (Gray) |

CFC-HC2000 |

Type III (1.0- 2.0 mil) |

MIL-A-8625 |

For type III anodizing, the alloy will determine your color.

6000-s: Gunmetal Grey

7000-s and 2000-s: bronze-gray

Due to variations we ask all of our customers to send a sample piece prior to the order if a specific color is required.

AA Aluminum Association

M10 Unspecified as Fabricated

C22 Medium Matte Etch

A41 Anodized Finish – Class I – Clear

A31 Anodized Finish – Class II – Clear

A44 Anodized Finish – Class I – Electrolytically Deposited Color (2-step)

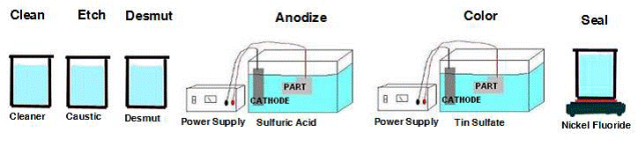

To achieve A44 (Color Coating), the method is shown in the following sketch:

The following are the steps and process parameters CFC follows for achieving the Color Coating.

1. RECEIVING: Upon receiving Customer Parts, a work order is assigned

2. UNPACKING: Parts are inspected and counted once container is opened for process. If container has visible damage, we will open and inspect immediately upon receiving and notify Customer of damages. Digital photos will be taken of damaged packaging and parts for records keeping purposes.

3. RACKING: To minimize handling, parts go directly from unpacking to racking. We will have an agreement with Customer as to the rack point on each part. We must have a positive contact on each part.

4. ETCHING: Following the cleaner, the parts are dipped in a caustic etch, normally 4 to 8 minutes, depending on the condition of the metal and the desired finish. The etch makes the aluminum surface uniform in appearance and helps to hide die marks or irregularities. Normally, any scratch that can be picked up by dragging a fingernail across the metal will be reduced but not totally removed. Any polishing or spot sanding in one area, or cross graining will be visible.

Tank temperature = 120-130 °F

Tank Mix: Sodium Hydroxide (Caustic Soda 50%) with high concentration of additives and chelating agents. Aluminum level is controlled from 120-160 grams/liter

Control Methods: Titration of Free Caustic, Titration of

Chelators, Titration of Additives

Note: Caustic gives the “matte” finish (AAMA C22 Medium Matte)

5. ETCH RINSE: As soon as the etching timer rings, parts must be removed from the etching tank and dipped into the etching rinse tank.

Tank temperature = Room temperature

Tank liquid: water

Note: Etching does not remove all impurities, rising is carried out to effectively finish the previous reaction and to prevent cross contamination between steps

6. DESMUTT: After rinsing, parts are dipped into a Dioxide Desmutt tank for 2-3 minutes to remove the smut left on the part after the etching process. The alloy of the aluminum will determine the time to remove the smut on the part, and parts may need to be dipped more than once to loosen impurities.

Tank temperature = Room Temperature

Tank mix: Houghton A-1714A, Dioxide Desmutt solution

7. DESMUTT RINSING: After leaving the desmutt tank, parts are dipped in a room temperature water rinse to remove any residue left on the surface of the aluminum. At this point, it may even be necessary to hoist parts to a rinse area and rinse with pressurized water to thoroughly remove all impurities.

8. ANODIZING: Once parts have been etched and thoroughly cleaned, they are moved to the sulfuric anodizing tank to be anodized per customer required specification. The time and amperage will be listed for each load, with the total surface area of the load and desired

thickness (i.e. greater than 0.7mil for Class I) being the determining factor.

Tank temperature = 68-72 °F

Tank mix: Sulfuric Acid, 175-185 grams/liter; Dissolved Aluminum, 8-12 grams/liter

Current Density: 12-15 Amps/Sq.Ft.

Control Methods: Titration of Sulfuric Acid; Titration of Dissolved Aluminum

9. ANODIZING RINSE: After anodizing, the parts are moved to a room temperature water rinse to remove any sulfuric acid left on the surface of the part.

10. MEASURING COATING THICKNESS: The coating thickness is measured and recorded for proper thickness specified. A coating reader must be used to take measurement in at least two sides of the part. (Readings should be greater than 0.70 mil for Class I)

Note: In case the coating is less than 0.70 mil; the parts are dipped into the anodizing tank again (step 9) for an additional 5 to 6 minutes (depending on load size), and steps 10 and 11 are repeated

11. ELECTROLYTIC COLORING: If parts are to remain Clear coated, and NOT to be colored, then they will skip to step #13. If the job specifies coloring, then the parts are dipped in the Electrolytic Coloring (Two-Step) tank, where coloring is accomplished by the electrical deposition of metallic particles near the base of the anodic pores. The depth of the metal deposit within the pore determines the color of the film, from champagne, through various bronzes, to black. The metal used is Tin (Sn). Color is determined by time and voltage applied, and is controlled by programmable timers (see photo at right) set by the operator.

Tank temperature = 68-72 °F

Tank mix: Tin Sulfate Solution

Control Methods: Titration of Additive; Titration of Free Sulfuric Acid

12. COLORING RINSE: As soon as the coloring timer alarm sounds, the parts are hoisted from the coloring tank and dipped immediately in a rinse tank of room temperature water, washing off any stannic oxide solids from the coloring bath, preventing contamination and lowering of the pH of the seal bath that follows. This is essential to preventing the formation of insoluble salts that could create smut problems in the seal bath.

13. SEALING: The parts are then lowered into the seal tank for 8 to 10 minutes. The seal is a nickel-based solution that acts to render the anodic coating inert, ensuring a surface that is non-staining, non-absorbing, non-reacting, and non-corrosive.

Tank temperature = 88-92 °F

Tank mix: Nickel Fluoride Solution, pH = 5.8-6.2

Control Methods: Titration of Additives, Measurement of pH, Measurement of Fluoride

14. SEAL RINSE: After sealing, the parts are moved to a hot water tank for 2-3 minutes to assist in sealing and to speed cure time.

Tank temperature = 120-130 °F

Tank mix: water

15. DRYING: The parts will be dried 30 minutes with a Steam heater prior to unracking.

16. UNRACKING: Cloth, knit gloves will be used for handling in unracking. Parts are either unracked to buggies (specially designed if necessary) or carried directly to the curing area.

17. CURING: 24-48 hours (depending on ambient temperature) is recommended for proper curing of the seal before packing. Part buggies are marked with the date and time they were unracked so that curing time can be tracked before packing begins.

18. MODIFIED DYE STAIN TEST: Random parts are selected for testing the quality of the seal using the industry standard Modified Dye Stain Test. Results will be reported for any failures.

19. PACKING: Packing will be done according to Customer’s instructions.